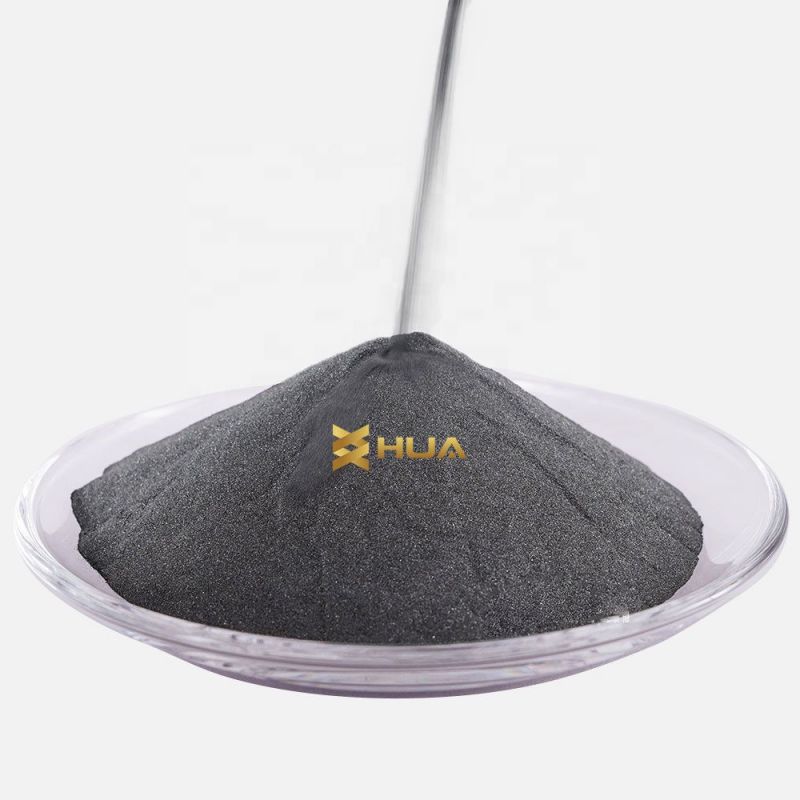

I-Metal alloy titanium powder ti6al4v powder yokuphrinta kwe-3d

Incazelo Yomkhiqizo

I-Ti6Al4V powder ebizwa ngokuthi i-TC4, iyingxube ye-α-β titanium enesilinganiso esiphakeme samandla-kuya-isisindo kanye nokumelana nokugqwala okuhle kakhulu.Ingenye ye-titanium alloys evame ukusetshenziswa kakhulu futhi isetshenziswa kabanzi ekumineni okuphansi futhi ukumelana nokugqwala okuhle kakhulu kuyadingeka embonini enjalo ye-aerospace kanye nezicelo ze-biomechanical (izimila kanye nama-prostheses).I-Ti6Al4V ngokuvamile ibhekwa "njengesisekelo" semboni ye-titanium. ngoba iyingxubevange ye-titanium esetshenziswa kakhulu kunazo zonke, engaphezu kuka-50% yenani eliphelele le-titanium.

I-TC4 titanium alloy inokumelana nokugqwala okuhle kakhulu.Inochungechunge lwezinzuzo ezinjengokuminyana okuphansi, amandla athile aphezulu, ukuqina okuhle, ukushisela okuhle nokunye.Isetshenziswe ku-aerospace, petrochemical, shipbuilding, imoto, imithi kanye nezinye izimboni.

Imininingwane yokucaciswa

| Ukwakhiwa kwe-Titanium nitride powder | |||

| Into | I-TiN-1 | I-TiN-2 | I-TiN-3 |

| Ubumsulwa | >99.0 | >99.5 | >99.9 |

| N | 20.5 | >21.5 | 17.5 |

| C | <0.1 | <0.1 | 0.09 |

| O | <0.8 | <0.5 | 0.3 |

| Fe | 0.35 | <0.2 | 0.25 |

| Ukuminyana | 5.4g/cm3 | 5.4g/cm3 | 5.4g/cm3 |

| usayizi | <1micron 1-3micron | ||

| 3-5micron 45micron | |||

| ukwanda okushisayo | (10-6K-1):9.4 impushana emnyama/ephuzi | ||

Ukucaciswa

| Titanium aluminium alloy(TC4)powder Properties | |||||

| Ububanzi besayizi | 0-25 um | 0-45 um | 15-45 um | 45-105um | 75-180um |

| I-Morphology | I-Spherical | I-Spherical | I-Spherical | I-Spherical | I-Spherical |

| I-PSD-D10 | 7 um | 15 um | 20 um | 53 um | 80 um |

| I-PSD-D50 | 15 um | 34 um | 35 um | awu 72um | 125 um |

| I-PSD-D90 | 24 um | 48 um | 50 um | 105 um | 200um |

| Ikhono lokugeleza | N/A | ≤120S | ≤50S | ≤25S | 23S |

| Ukuminyana Okubonakalayo | 2.10g/cm3 | 2.55g/cm3 | 2.53g/cm3 | 2.56g/cm3 | 2.80g/cm3 |

| Okuqukethwe komoyampilo(wt%) | O:0.07-0.11wt%,izinga le-ASTM:≤0.13wt% | ||||

Siphinde sinikeze ngezinsizakalo ezenziwe ngezifiso

Welcom uzodinga i-COA nesampula yamahhala yokuhlolwa

I-SEM

| I-Titanium aluminium alloy(TC4)powder Izinto eziyinhloko: | ||

| Al | V | Ti |

| 5.50-6.75 | 3.50-4.50 | U-Bal |

Isicelo

1. ukwenziwa kwe-laser / electron beam (SLM/EBM).

2. i-powder metallurgy (PM) nezinye izinqubo.

3. izinhlobo ezihlukahlukene zamaphrinta ensimbi e-3D, okuhlanganisa i-Renishaw, i-Renishaw, i-Germany EOS (uchungechunge lwe-EOSINT M), i-Concept Laser, izinhlelo ze-3D nezinye izinto zokuncibilika kwe-laser.

4. ukwakhiwa kwezingxenye ze-aerospace, Ama-Aeroengine Blades nezinye izingxenye zomsebenzi wokulungisa.

5. imishini yezokwelapha.