I-Additive Production Powder 316l Yensimbi Engagqwali Yokuphrinta kwe-3d

Incazelo Yomkhiqizo

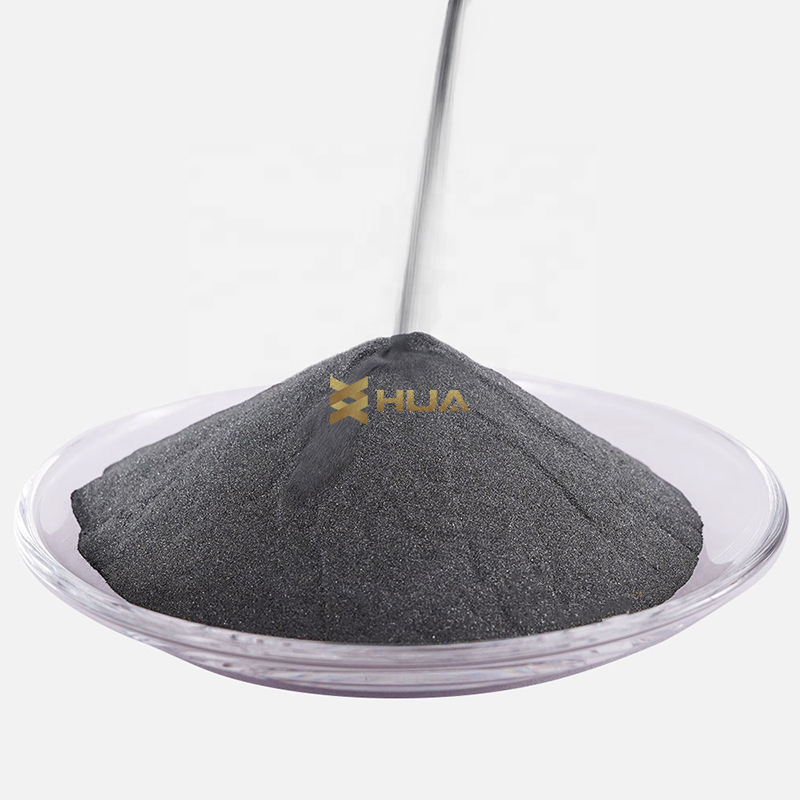

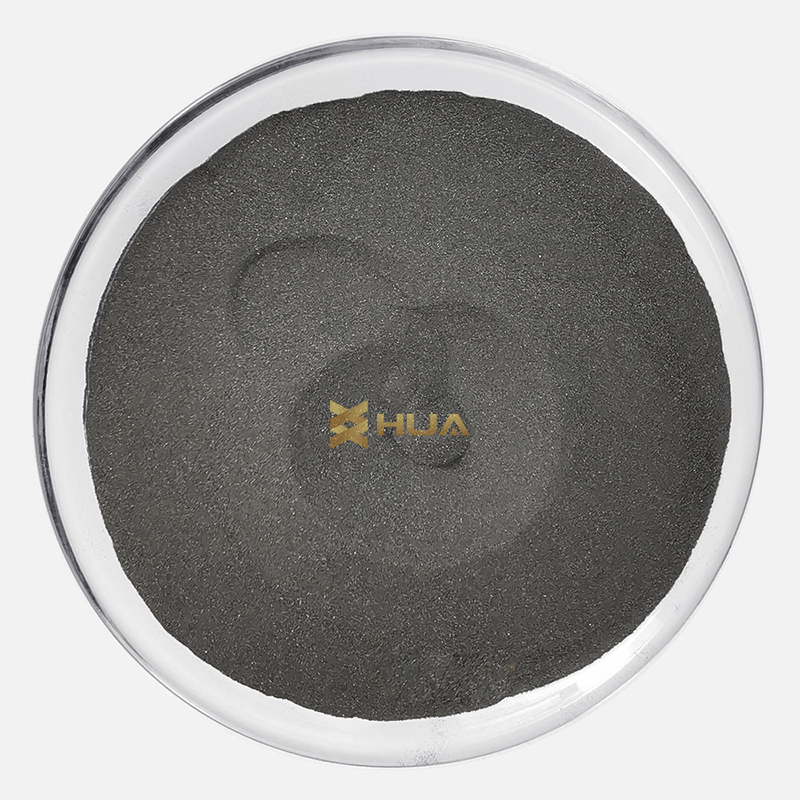

Impushana yensimbi engagqwali yenziwa inqubo ye-atomization yamanzi futhi inokumelana nokugqwala okuhle nokuqina.Impushana yensimbi engagqwali inezinhlobonhlobo zokusetshenziswa kwezimboni.

Nikeza impushana yensimbi engagqwali ehlukahlukene enosayizi wezinhlayiyana ezahlukene.

Ngokusebenzisa

1.Hot Isostatic Pressing

2.Metal Umjovo Molding

3.3D ukuphrinta

4.Ukufutha okushisayo

Ngokwenqubo yokukhiqiza

1.Atomization yamanzi

2.Water gas kuhlangene atomization

3.Igesi atomization

4.Vacuum atomization

Imininingwane yokucaciswa

| I-Stainess steel powder ukwakheka% | |||||||||

| Ibanga | Cr | Ni | Mo | Nb | Cu | S | P | C | Si |

| 303 | 17-19 | 8-13 |

|

|

| 0.15-0.3 | ≤0.2 | ≤0.15 | ≤1 |

| 304 | 18-20 | 8-12 |

|

|

| ≤0.03 | ≤0.04 | ≤0.08 | ≤1 |

| 316 | 16-18 | 10-14 | 2-3 |

|

| ≤0.03 | ≤0.04 | ≤0.08 | ≤1 |

| 303L | 17-19 | 8-13 |

|

|

| 0.15-0.3 | ≤0.2 | ≤0.03 | ≤1 |

| 304L | 18-20 | 8-12 |

|

|

| ≤0.03 | ≤0.04 | ≤0.03 | ≤1 |

| 316L | 16-18 | 10-14 |

|

|

| ≤0.03 | ≤0.04 | ≤0.03 | ≤1 |

| 317L | 18-21 | 12-16 | 3-4 |

|

| ≤0.03 | ≤0.04 | ≤0.03 | ≤1 |

| 314 | 24-27 | 18-21 |

|

|

| ≤0.03 | ≤0.04 | ≤0.2 | 1.5/2.5 |

| 310 | 24-26 | 19-22 |

|

|

| ≤0.03 | ≤0.04 | ≤0.08 | ≤1 |

| Idatha ye-303LSC | 17-19 | 8-13 |

|

| 2 | 0.15-0.3 | ≤0.2 | ≤0.03 | ≤1 |

| Idatha ye-304LSC | 17-19 | 8-13 |

|

| 2 | ≤0.03 | ≤0.04 | ≤0.03 | ≤1 |

| Idatha ye-316LSC | 16-19 | 10-14 | 2-3 |

| 2 | ≤0.03 | ≤0.04 | ≤0.03 | ≤1 |

| 410L | 11.5-13.5 |

|

|

|

| ≤0.03 | ≤0.04 | ≤0.03 | ≤1 |

| 430L | 16-18 |

|

|

|

| ≤0.03 | ≤0.04 | ≤0.03 | ≤1 |

| 434L | 16-18 |

| 0.75-1.25 |

|

| ≤0.03 | ≤0.04 | ≤0.08 | ≤1 |

| 434LNB | 16-18 |

| 0.75-1.25 | 0.4-0.6 |

| ≤0.03 | ≤0.04 | ≤0.03 | ≤1 |

| 410 | 11.5-13.5 |

|

|

|

| ≤0.03 | ≤0.04 | ≤0.25 | ≤1 |

| 420 | 12-14 |

|

|

|

| ≤0.03 | ≤0.04 | 0.25/0.35 | ≤1 |

| 430 | 16-18 |

|

|

|

| ≤0.03 | ≤0.04 | ≤0.08 | ≤1 |

| 434 | 16-18 |

| 0.75-1.25 |

|

| ≤0.03 | ≤0.04 | ≤0.08 | ≤1 |

| 440 | 16-18 |

|

|

|

| ≤0.03 | ≤0.04 | 0.9/1.2 | ≤1 |

| 17-4PH | 15-17.5 | 3-5 |

| 0.15-0.456 | 3-5 | ≤0.03 | ≤0.04 | ≤0.07 | ≤1 |

| 15-5PH | 14-15.5 | 3.5-5.5 |

|

| 2.5-4.5 | ≤0.03 | ≤0.04 | <=0.07 | ≤1 |

Isicelo

Impushana yensimbi engagqwali ingasetshenziselwa ukufafaza okushisayo, i-powder metallurgy, i-powder metallurgy press sintering (PM), isihlungi sokubumba umjovo (MIM), njll., okuqukethwe komoyampilo we-atomization yamanzi<4000PPM, igesi atomization<1000PPM.

Inzuzo ye-HUARUI yensimbi engagqwali powder

● Ngisho nokwakheka kwempushana, ukungcola okuncane

●I-sphericity ephezulu

● Okuqukethwe komoyampilo omncane

●Ukugeleza okuhle

●Ukuminyana okuphezulu, ukuminyana kokuthepha okuphezulu

●Impushana engenalutho encane, impushana yesathelayithi encane

Uhlelo lokulawula ikhwalithi

I-1.Huarui inohlelo oluqinile lokuphatha ikhwalithi.Sihlola imikhiqizo yethu kuqala ngemva kokuqeda ukukhiqiza kwethu, futhi siyahlola futhi ngaphambi kwakho konke ukulethwa, ngisho nesampula.Futhi uma udinga, singathanda ukwamukela inkampani yangaphandle ukuthi ihlole.Impela uma uthanda, singakunikeza isampula ozoyihlola.

2.Ikhwalithi yomkhiqizo wethu iqinisekiswa yiSichuan Metallurgical Institute kanye ne-Guangzhou Institute of Metal Research.Ukusebenzisana nabo kwesikhathi eside kungonga isikhathi esiningi sokuhlola kumakhasimende.